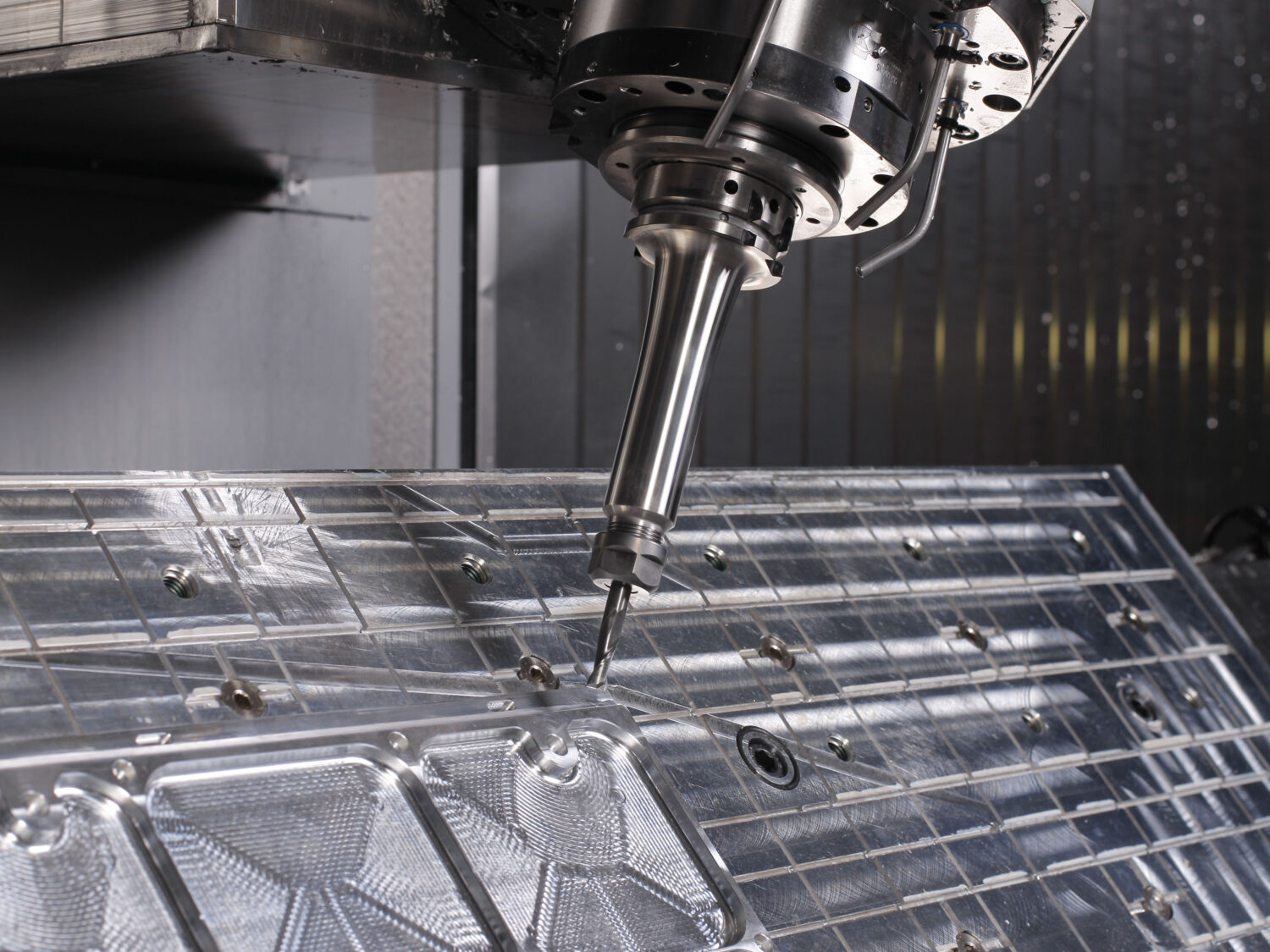

CNC milling

BWB manufactures precise aluminum components on state-of-the-art milling centers. For optimal machining, we use vacuum clamping technology in addition to standard vices. Thanks to 5-axis simultaneous milling and, if necessary, specially made fixtures, we are also able to produce particularly complex workpieces. Due to our automation incl. zero point clamping system, we increase flexibility and process reliability, shorten throughput times and can reduce setup times to a minimum.

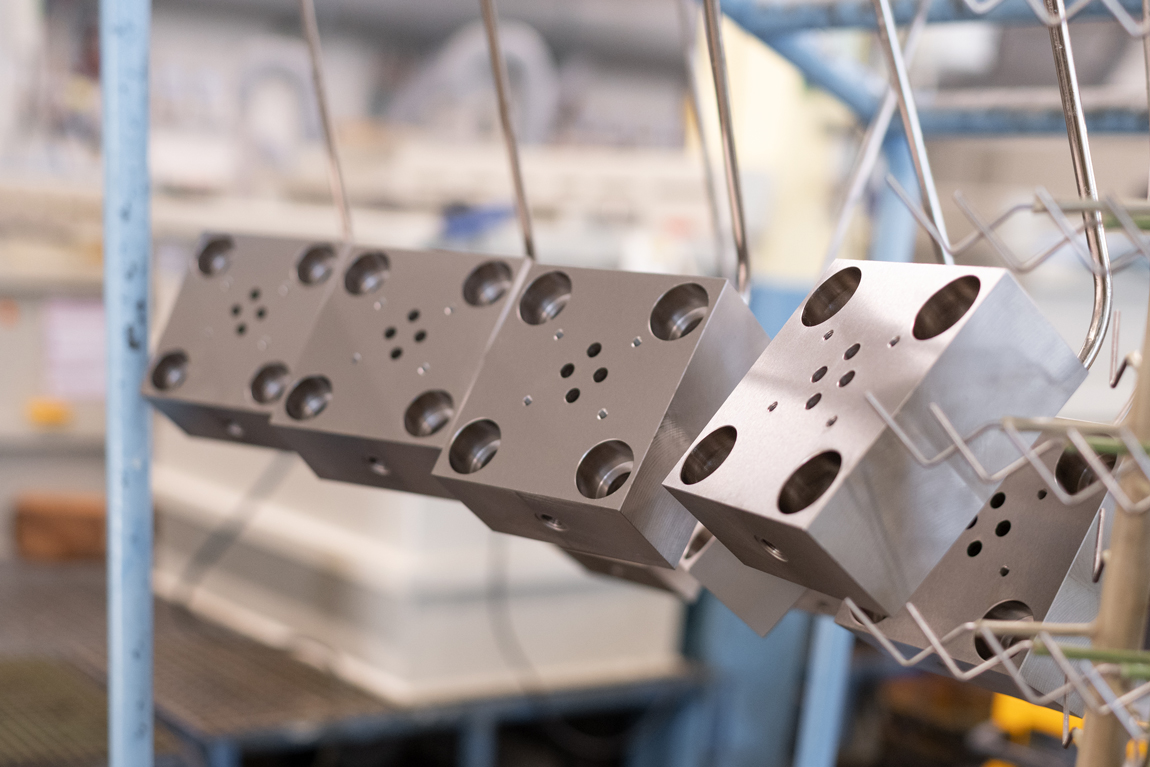

Long part machining

Whether it is CNC milling up to 3,000 mm or profile machining up to 6,500 mm, BWB always offers the right solution for customers' individual requirements.

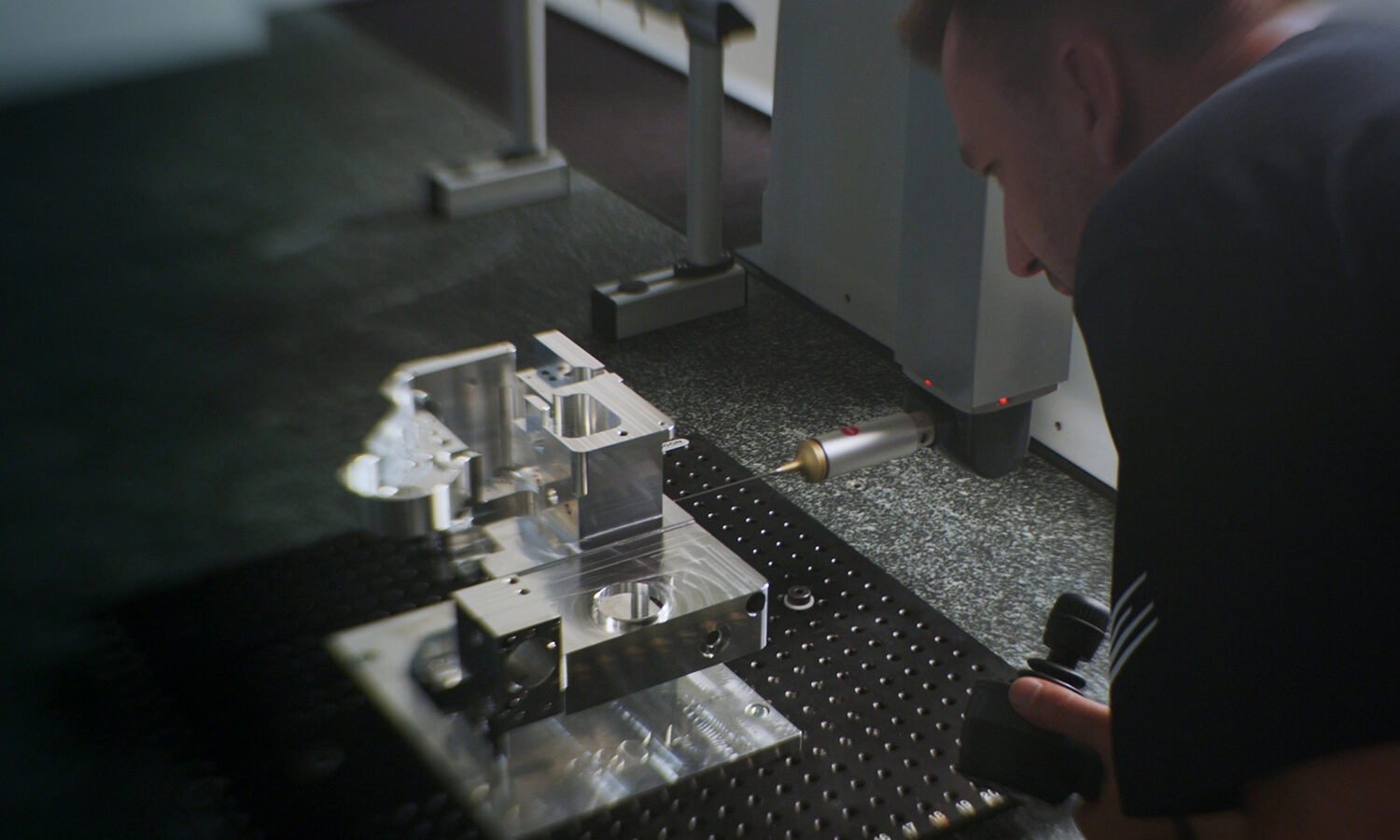

3D fairs

BWB manufactures aluminum components of the highest quality. To ensure that tolerance requirements in the micrometer range are met, we not only use in-process controls with measurements directly on the machine, but also have a modern 3D measuring machine for final inspection.

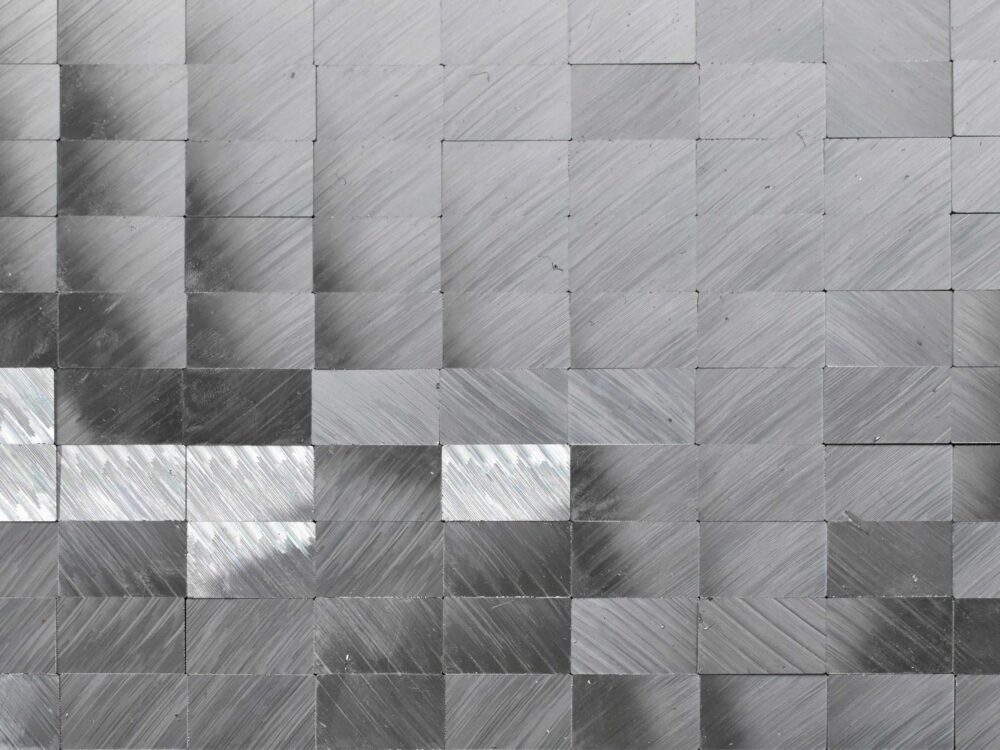

Surface design

From alloy selection to machining - at BWB, everything is geared towards the perfect surface finish. When BWB manufactures and finishes your products, you benefit from the entire value chain from a single source.

Laser engraving

For permanent traceability, for attaching logos and lettering or for marking operating elements - BWB will laser mark your parts on request.

You choose between laser engraving or blackmarking.

Assembly of components

On request, we assemble the coated parts of our customers into complete assemblies. We also take care of the procurement of all required third-party components.

Contact

Thomas Furger

Manager Mechanical Processing

+41 58 861 93 55 thomas.furger@bwb-group.comBWB-Betschart AG

Dallenwilerstrasse 20

CH-6370 Stans-Oberdorf

+41 58 861 93 00