Insight into the production

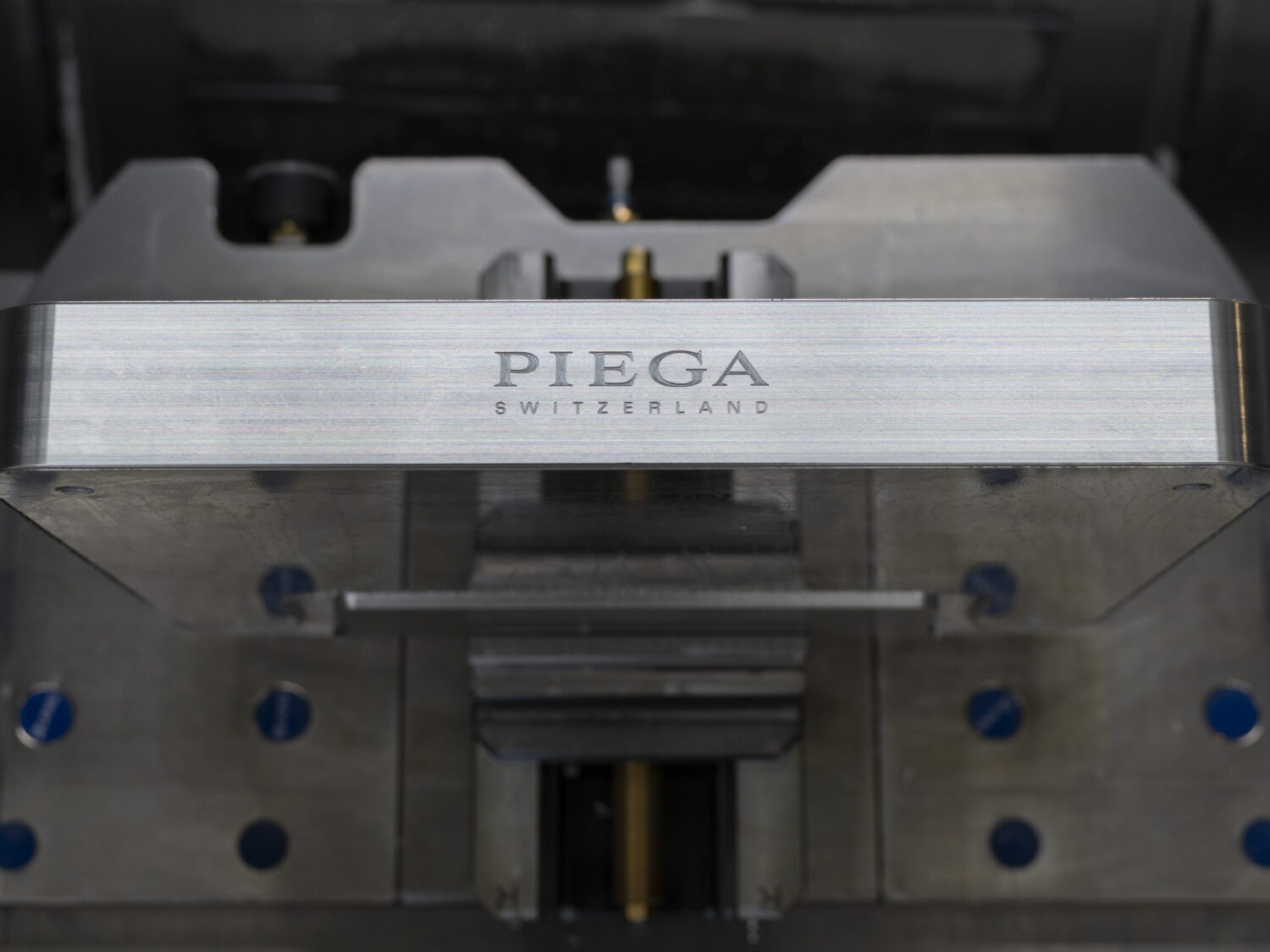

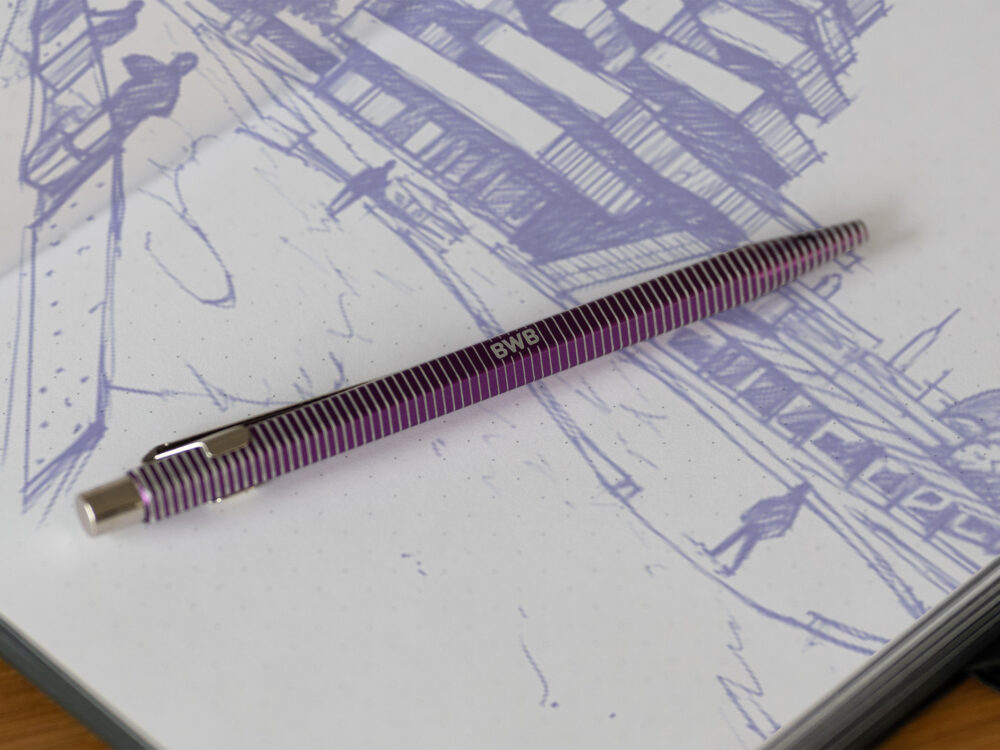

In the Stans plant of BWB Oberflächentechnik, the PIEGA housing parts are milled, inscribed, ground and anodized. CNC machining requires several operations with nearly twenty different tools. These remove material, round edges and mill threads. The smallest cutter, half a millimeter in diameter, draws the logo into the surface.

More than anodising

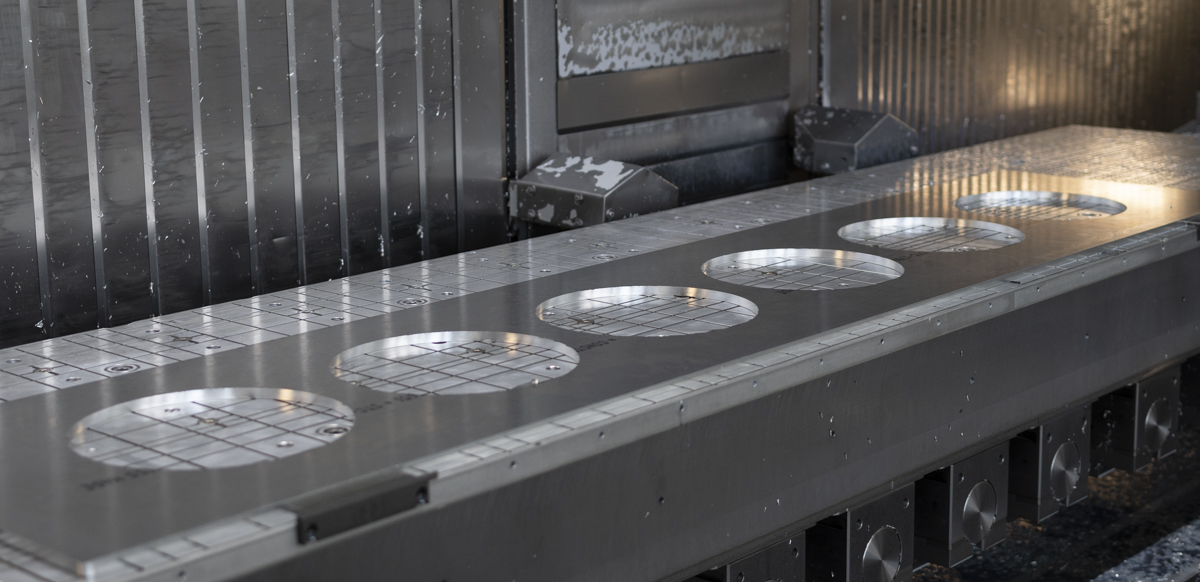

"Parts up to a dimension of 3'000x600x700mm can be machined on our CNC machines. A machining center with automatic loading system enables efficient machining of small to large series," says Thomas Furger, head of the mechanical department at BWB-Betschart AG. His team offers finished aluminum components from a single source - from material procurement to mechanical processing and surface finishing.