Competence Center for precious metals

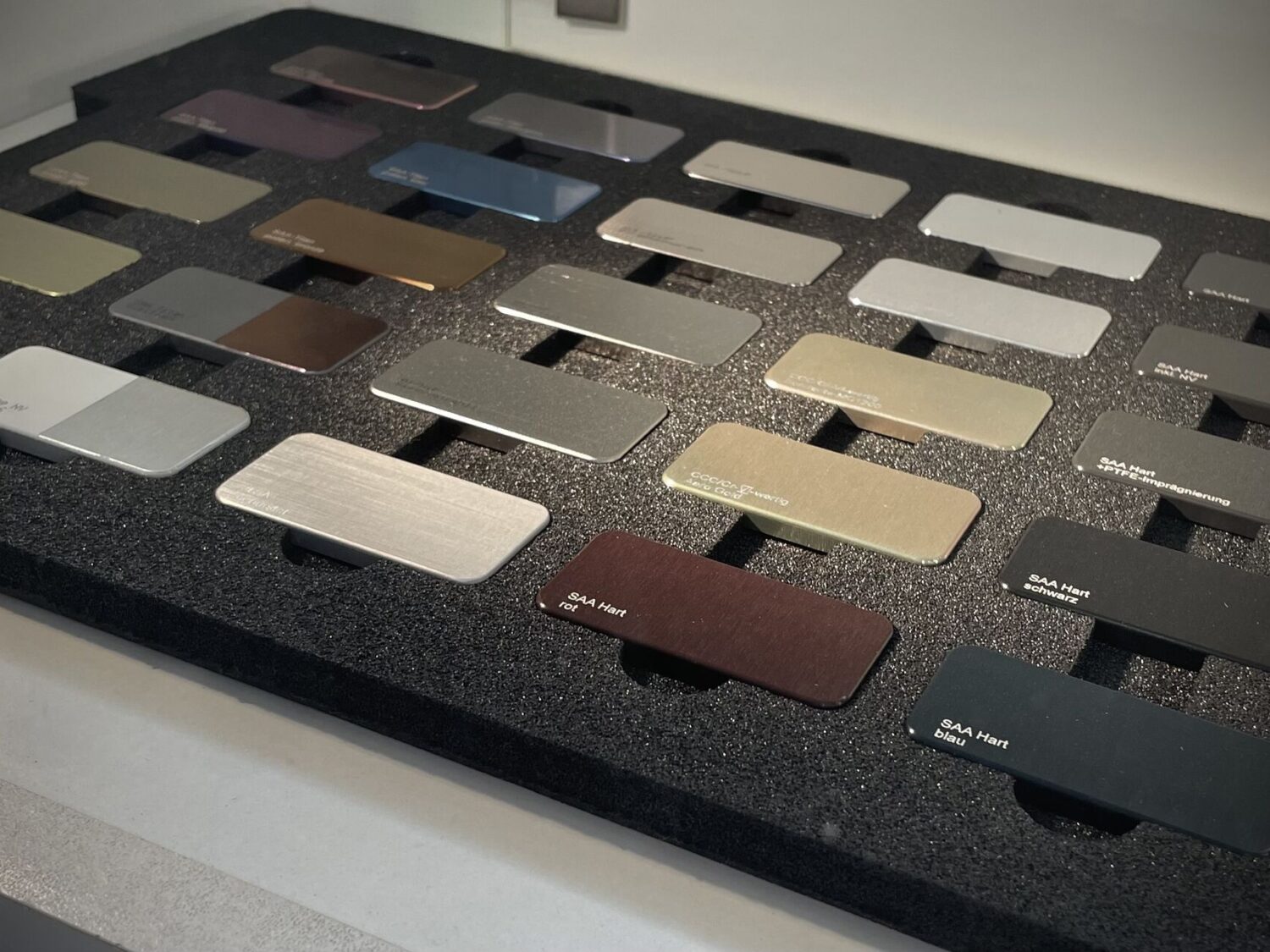

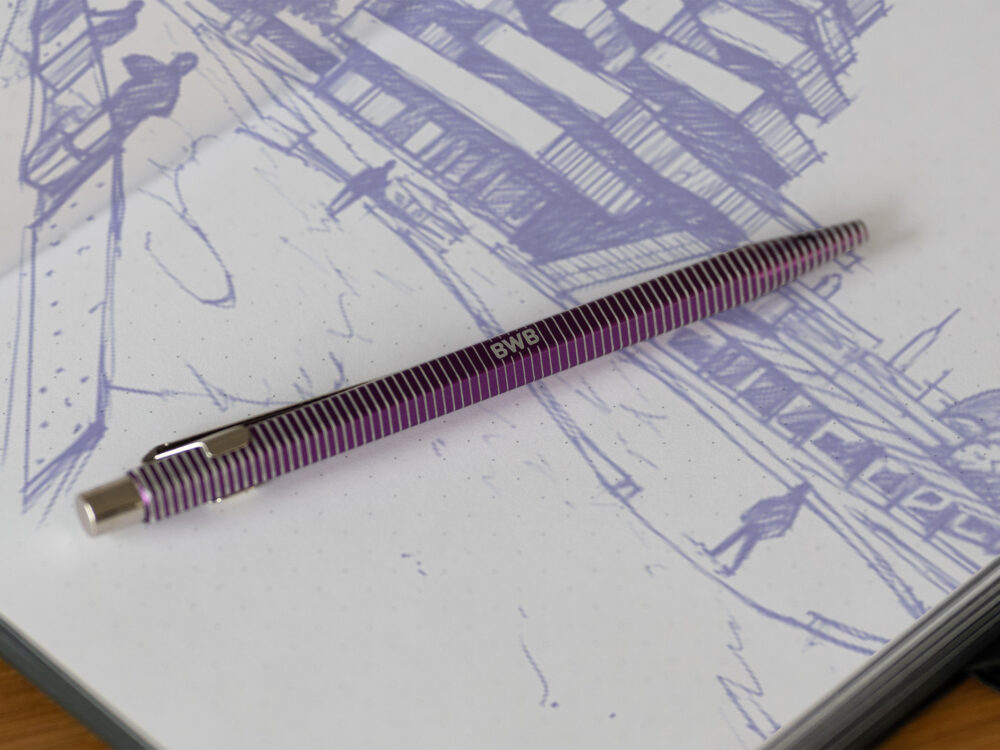

The BWB-Ampho factory is located in La Chaux-de-Fonds, in the heart of the Swiss watch industry. As a supplier to the watch and jewelry industry, the plant specializes in the assembly of small parts using welding and brazing processes, a wide range of electrolytic surface treatments, sand and glass bead blasting, and the processing of stainless steel cables.

Contact

Bernhard Mayer

Managing Director

+41 58 861 95 45 bernhard.mayer@bwb-group.comBWB-Aloxyd AG

Industriestrasse 15

CH-3294 Büren a.A.

+41 58 861 95 00