Dimensionally accurate coatings

The application of a protective layer leads to an increase in the size of the component. To ensure that the dimensions remain true to size, the increase must be neutralized by chemical erosion or already taken into account during mechanical processing. Tolerances agreed in advance can be maintained when coating to size.

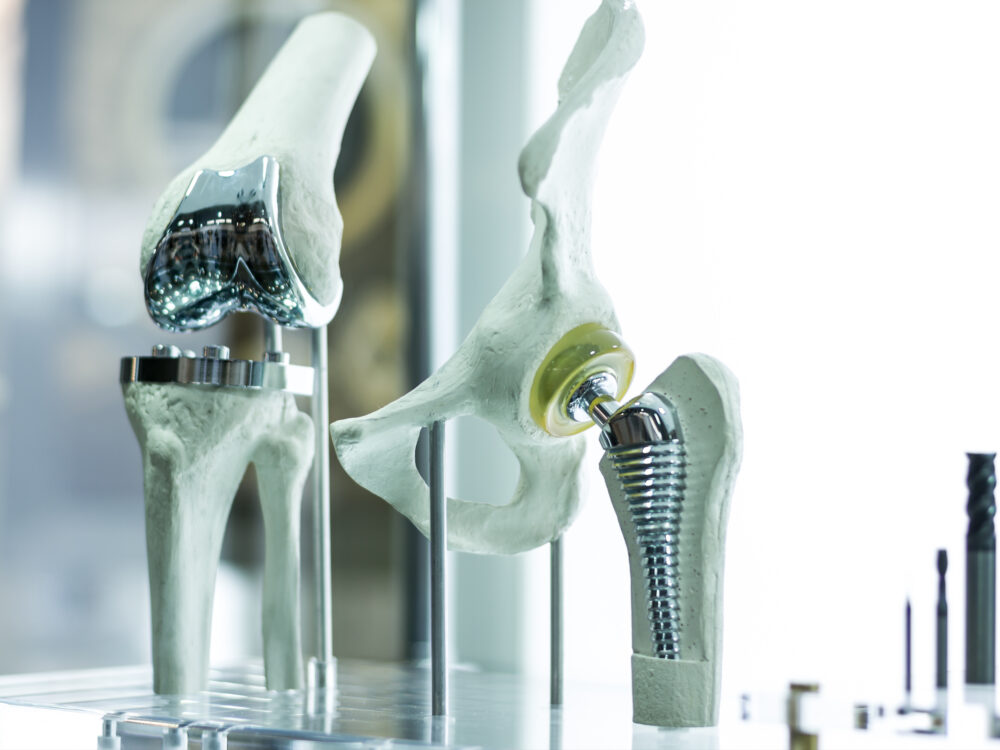

Hard anodising for added durability

Hard anodising can produce very resistant surfaces on aluminium components. In contrast to normal anodising, this process uses high currents and temperatures around freezing point to achieve a particularly high Vickers hardness of up to 550 HV.

Hard anodising PTFE

For even better sliding properties, hard anodised parts can be additionally impregnated with PTFE. PTFE impregnation is often used in dry lubrication and in bearings and seals to minimize friction.

Ematal anodising

Ematal anodising is used when friction is to be minimized by mechanical contact (e.g. in plain bearings), by a flowing medium (e.g. valve housings and nozzles for gases or liquids) or a combination thereof (in pneumatics and hydraulics).

Oversize anodising

BWB Surface Technology anodises aluminium components with a weight of up to 2 tons, a length of 22 meters and a height and width of 2.2 x 1.3 meters.