A key component of Aerolite systems are the machined integral bases. These are aluminum assemblies for helicopter floors that provide attachment points for custom equipment, rescue stretchers and seats. The complex milled parts in lightweight construction meet the requirements of aviation, are extremely robust and durable.

Integralboden vor Beschichtungsprozess, Bild: BWB Oberflächentechnik

To withstand the mechanical stresses and be protected against corrosion, the integral bases are hard anodized. While most hard anodizing systems proved to be too small for the components, BWB-Altenrhein convinced with the special Permalux hard anodizing process for components up to 7500 x 1200 x 2200 mm.

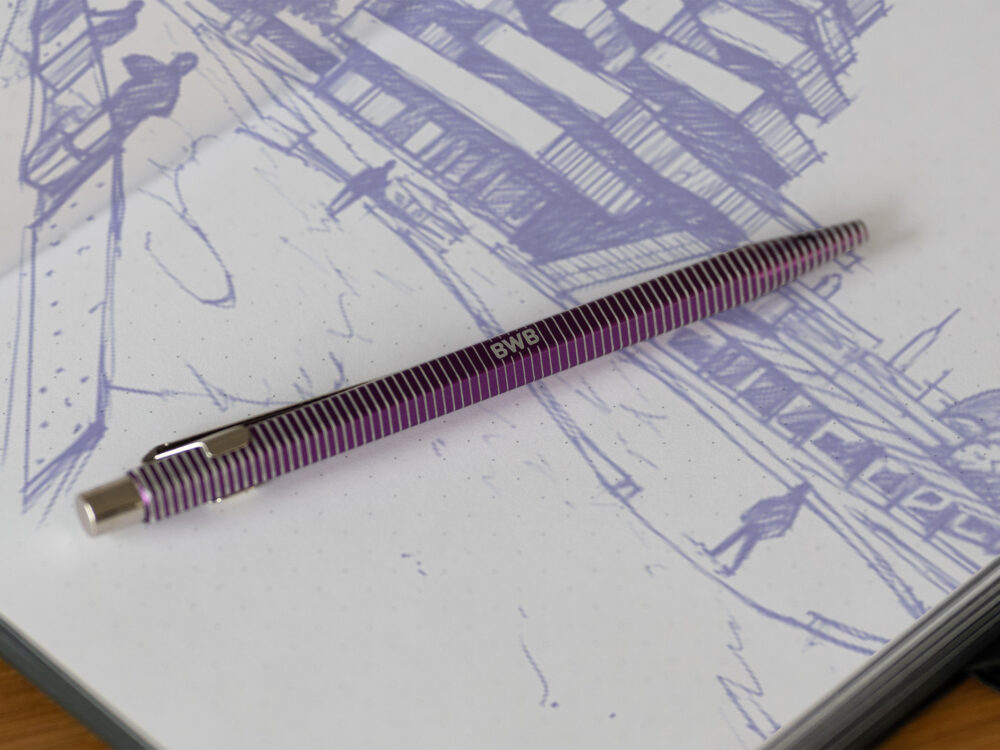

Integralboden mit Permalux-Beschichtung, Bild: BWB Oberflächentechnik

But how do the layering properties of Permalux compare to commercially available hard anodized coatings? The BWB laboratory has investigated this question and subjected the surfaces of customer components to an endurance test. The test values of the Permalux coating on the alloy EN AW-6082 are impressive: The coating hardness is 20% higher than conventional GSX hard anodized coatings and no corrosion spots appear after 168 hours of salt spray testing.

Permalux combines aesthetics with the highest resistance to mechanical and chemical influences. For applications in aviation, mechanical engineering and architecture. Are you also looking for the best protection for a big throw? We will be happy to advise you.