The advantages of Ematal

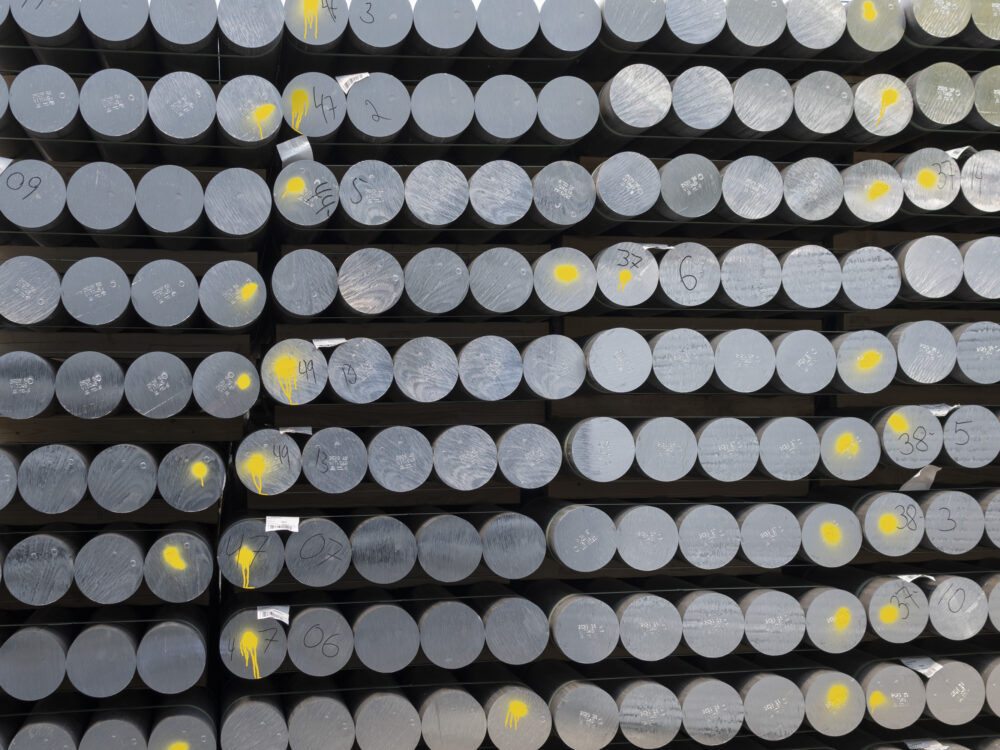

Ematal anodised aluminum parts provide a wear-resistant, smooth and virtually non-porous surface that ensures reliable protection against abrasion and corrosion.

The process results in a very low material build-up and is therefore particularly suitable for applications with increased dimensional stability requirements.

Protection against abrasion

Ematal is used when friction is to be minimized by mechanical contact (e.g. in plain bearings), by a flowing medium (e.g. valve bodies and nozzles for gases or liquids) or a combination of these (in pneumatics and hydraulics).

Hard Ematal for added durability

In a specially controlled process, the coating thickness can be increased threefold. The 30 µm thick hard Ematal layers protect parts from particularly high mechanical stresses. As a result, results of up to 600 HV can be achieved.

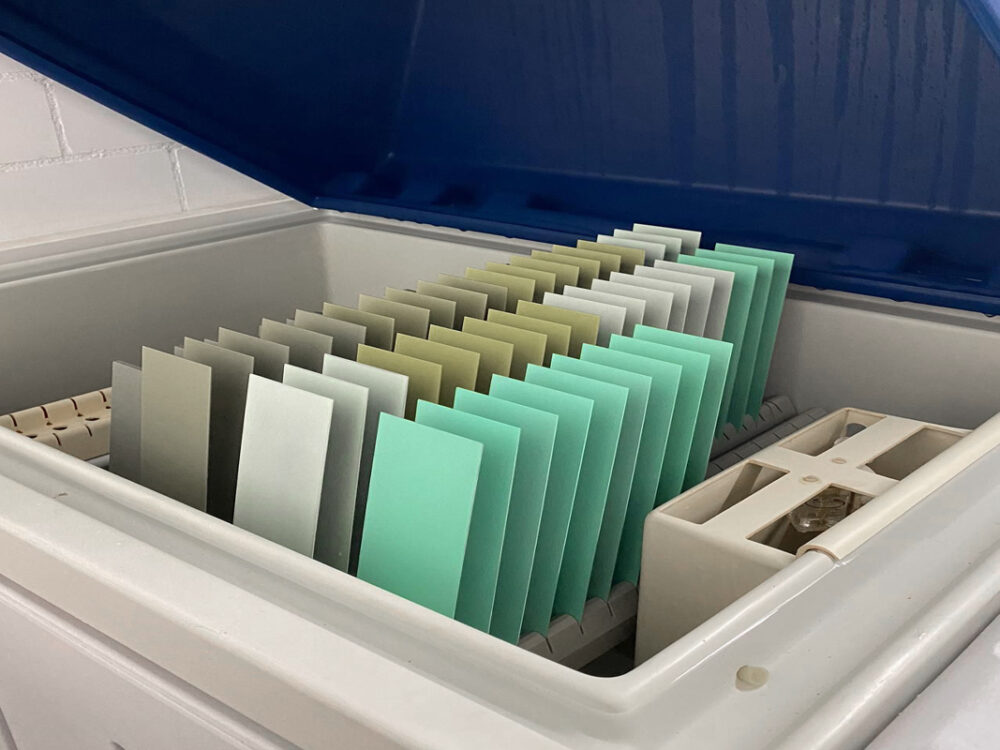

Optical properties

The Ematal layers have an enamel-like appearance and, depending on the alloy, a light gray to bronze color. Before compaction, it is also possible to enrich the layer with a black dye, which creates a very precious, scratch-resistant surface for visible parts.

Chemical resistance

Ematal has a very high resistance to various acids, salts, solvents and lubricants.

Sampling

We are happy to offer you the opportunity to sample the Ematal coating on your workpiece so that you can see for yourself its resistance and suitability for your application.