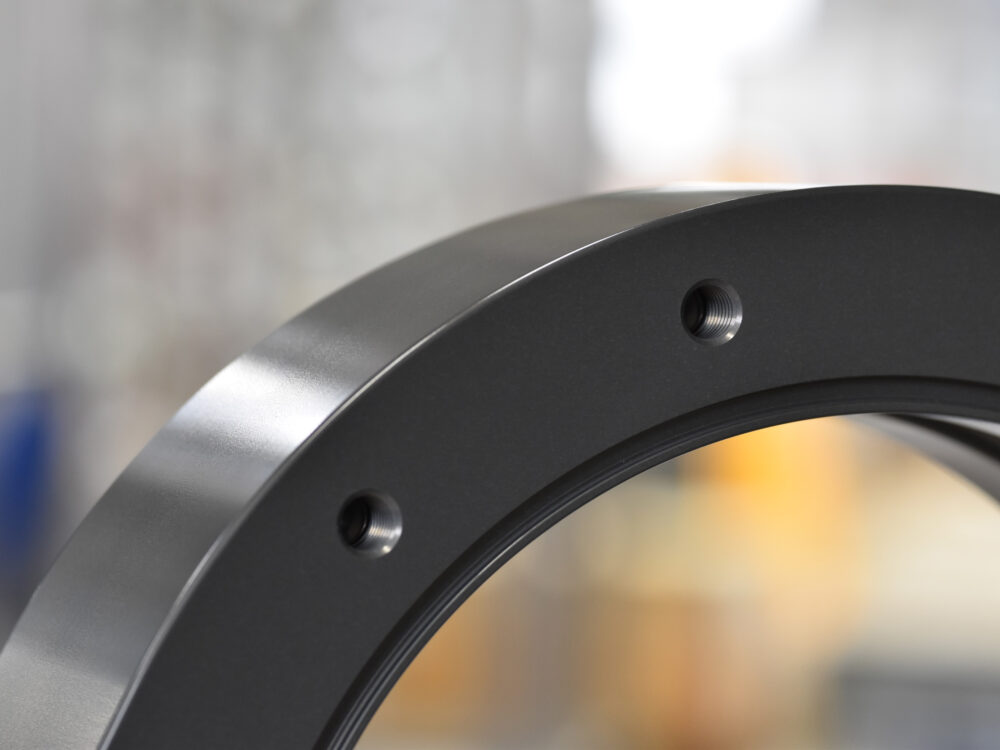

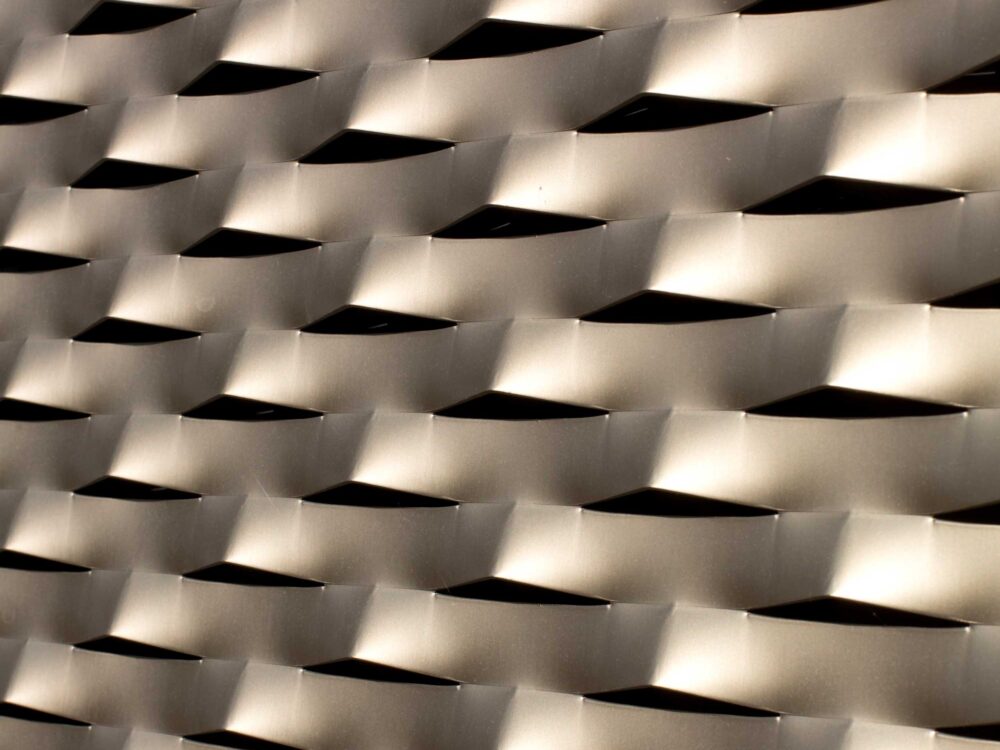

Symbiosis of sound and design

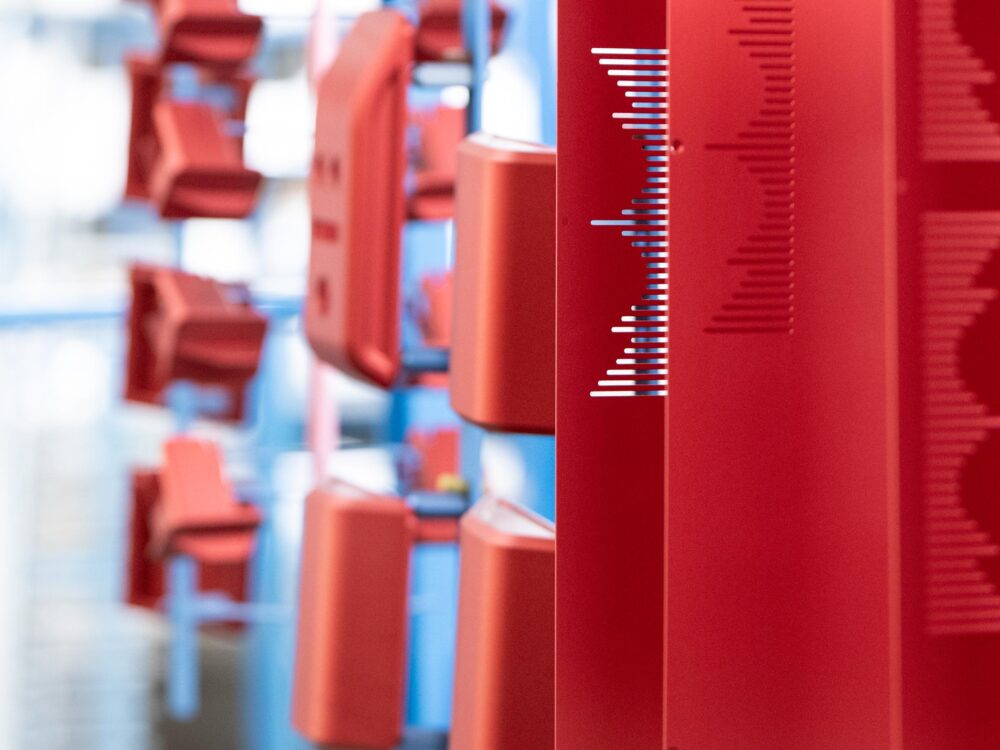

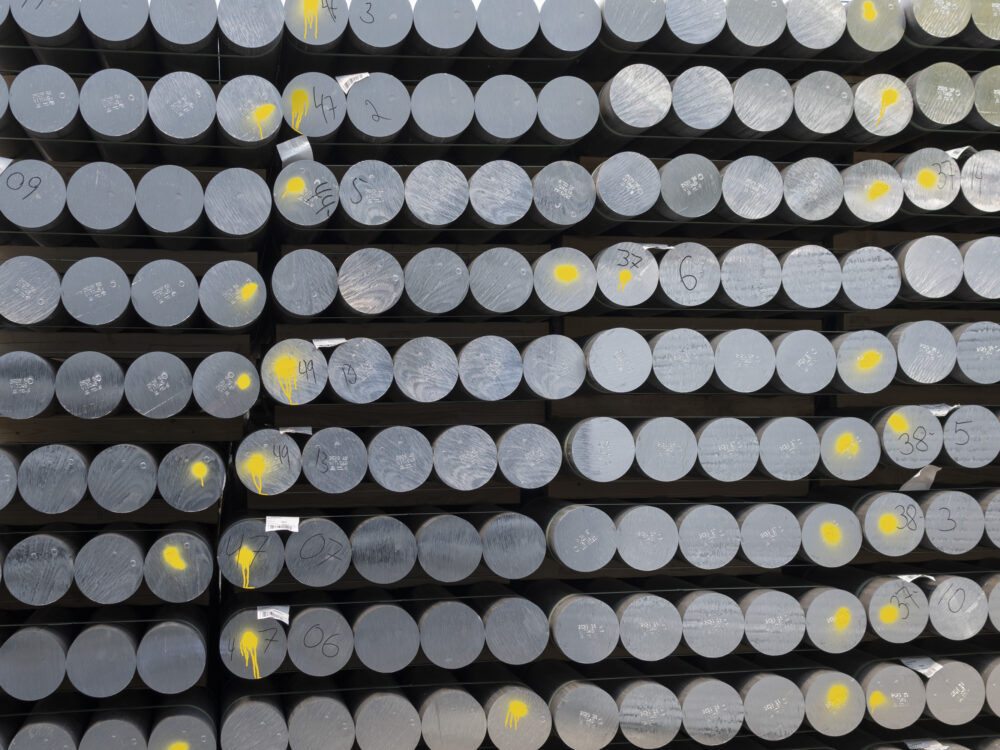

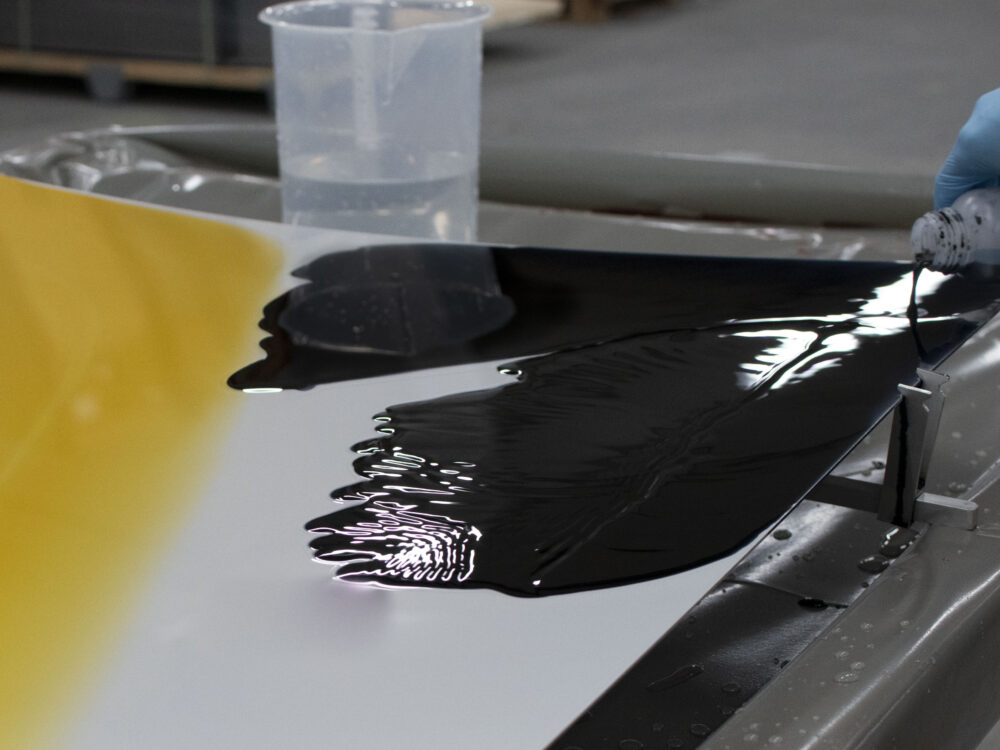

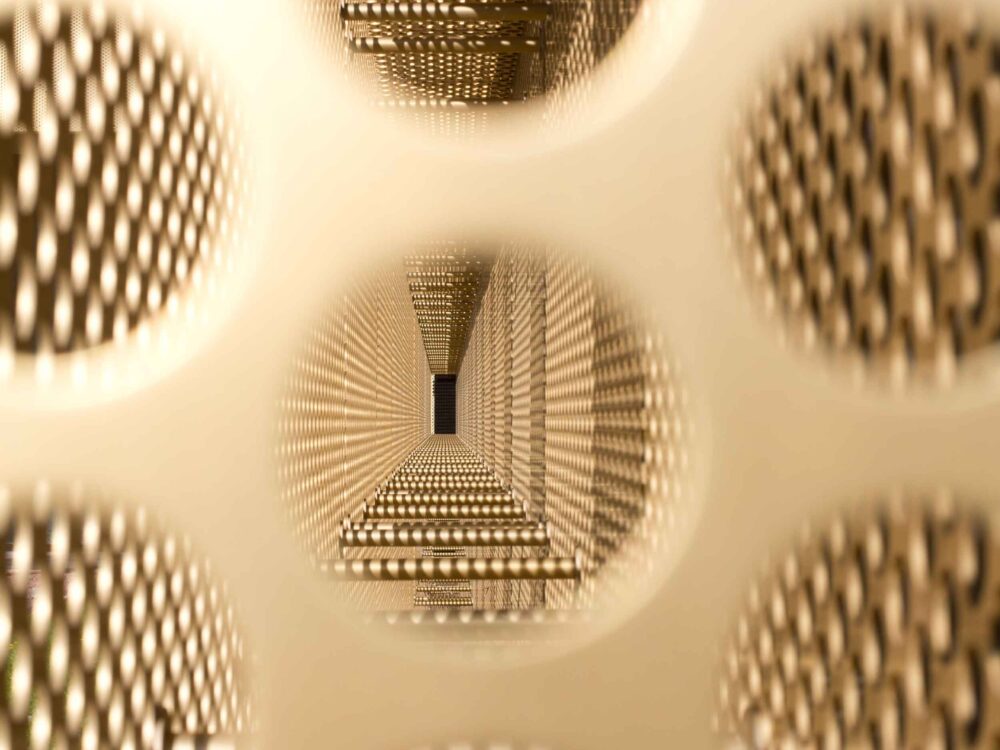

For over 35 years, the name PIEGA has stood for top-class loudspeakers that focus not only on sound, but also on the aesthetic experience. Now, through the innovative partnership with BWB Surface Technology as part of the "PIEGA COAX EXCELLENCE" program, this outstanding combination is being taken to a new level.